SetHome>> Equipment Display

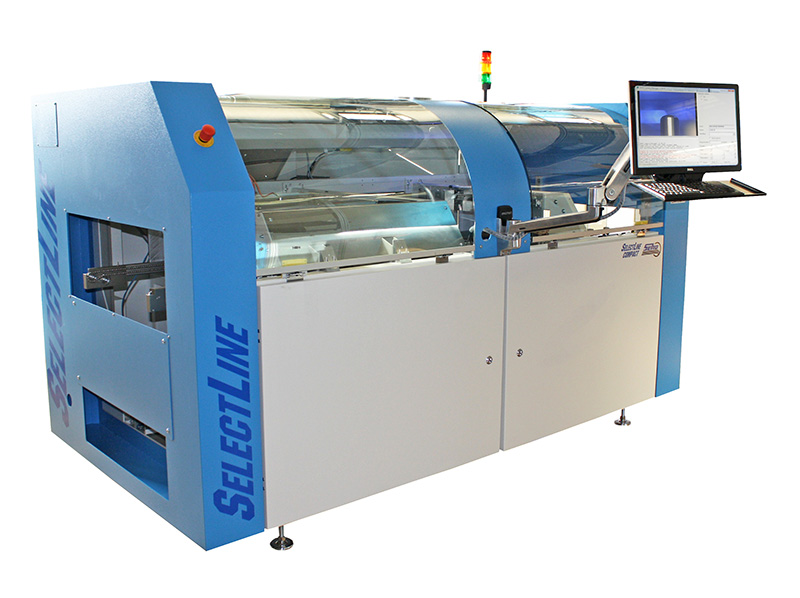

Electronic productions face new manufacturing challenges more and more frequently. Besides high quality requirements at low production cost, there are also an increasing number of product variants and flexible reactions to fluctuation in demand.

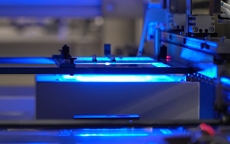

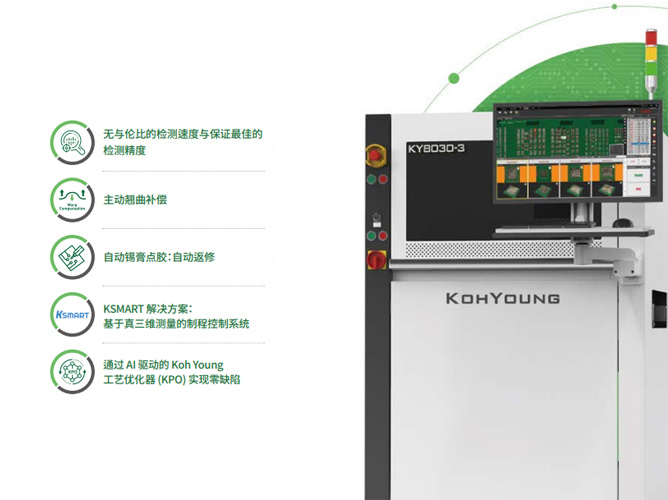

The SEHO LeanSelect is particularly designed to meet these challenges, featuring highest flexibility and outstanding return of invest. While the entire process is fully automated, loading and unloading of assemblies is done manually on two separate conveyors. This allows processing of up to five carriers at the same time. The work stations are arranged in a counter-clockwise U-shape, thus consistently following the Lean Equipment Design Guidelines.

■ smallest footprint of only 2.5 m²

■ ideally suited for up-to-date manufacturing islands

■ high flexibility and productivity: electro-magnetic soldering unit with miniwave nozzle or multi-nozzle dip tool

■ high energy efficiency: only one axis to position fluxer and soldering unit

■ high production rate: up to five carriers in process at the same time

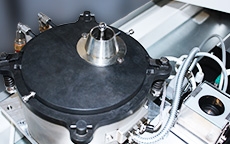

■ patented, automatic ultrasonic cleaning of solder nozzles ensures a reliable process

■ 100 % process control

■ AOI system SEHO PowerVision integrable

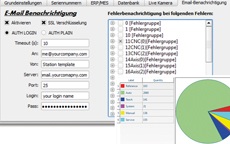

■ efficient programming, online or offline, and with mcServer ready for Industry 4.0