SetHome>> Equipment Display

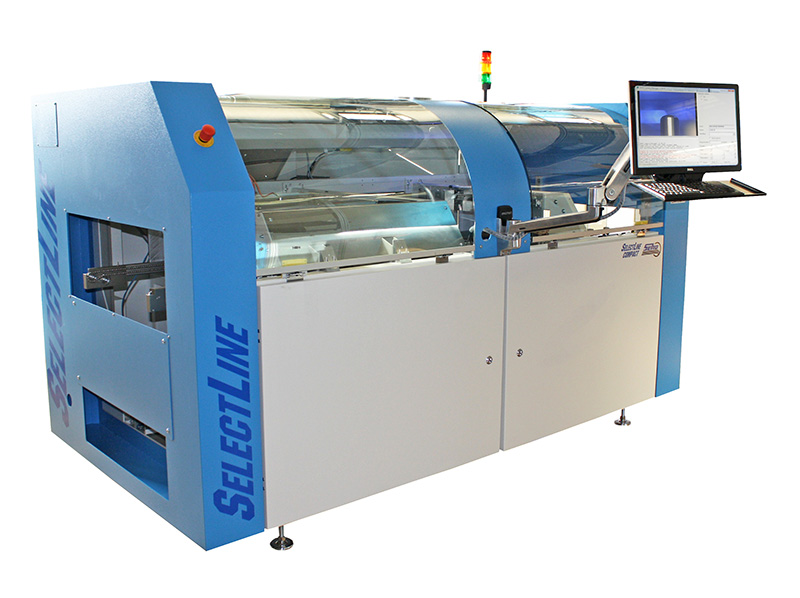

The MaxiSelective-HS represents the high speed selective soldering system from SEHO. It is the perfect solution when highest soldering quality and shortest cycle times are required.

Parallel processes in the fluxing, preheating and soldering area, simultaneous contact of all solder joints with product specific multi nozzle soldering tools as well as the parallel transfer of the assemblies to the next work station make this „one product machine“ the ideal system for mass production.

Two basic machine versions of the MaxiSelective-HS that can be equipped with four or six stations working in parallel, offer the flexibility needed to meet your individual production requirements. Additional buffer stations at the inlet and outlet of the machine complete this high speed system. In order to meet complex production challenges or to respond to increasing manufacturing volumes, the MaxiSelective-HS can be expanded with additional mo-dules or it may be combined with other machine types, also at any later date.

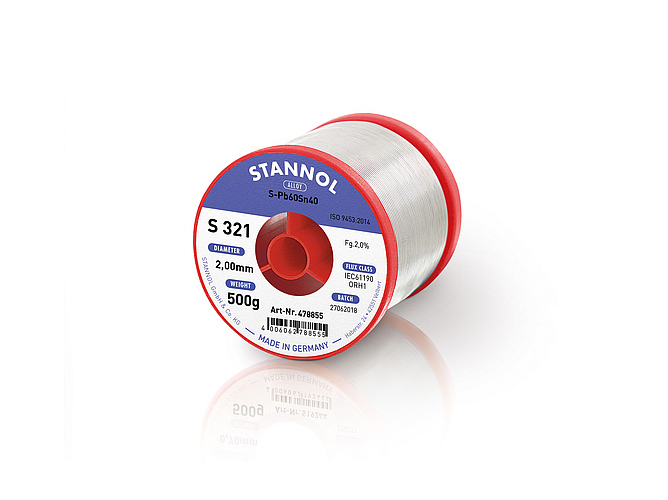

Of course, the MaxiSelective-HS provides outstanding features for automated process control, characteristic for selective soldering systems from SEHO. Flux quantity monitoring, gradient-controlled temperature profiles, solder level control with automatic wire supply and an automated wave height control are only some of the machine’s highlights.

■ high speed selective soldering system with shortest cycle times less than 20 seconds

■ this “one product system” is the ideal solution for mass production

■ parallel processes in the fluxing, preheating and soldering area + parallel transfer of assemblies to the next work stations = shortest throughput times

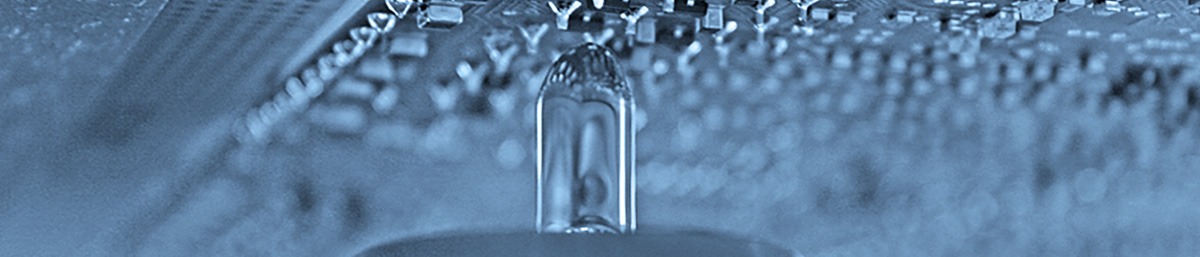

■ high precision miniwave soldering process with product specific multi nozzle tools

■ nitrogen inertion of the multiwaves guarantees highest soldering quality and minimum maintenance

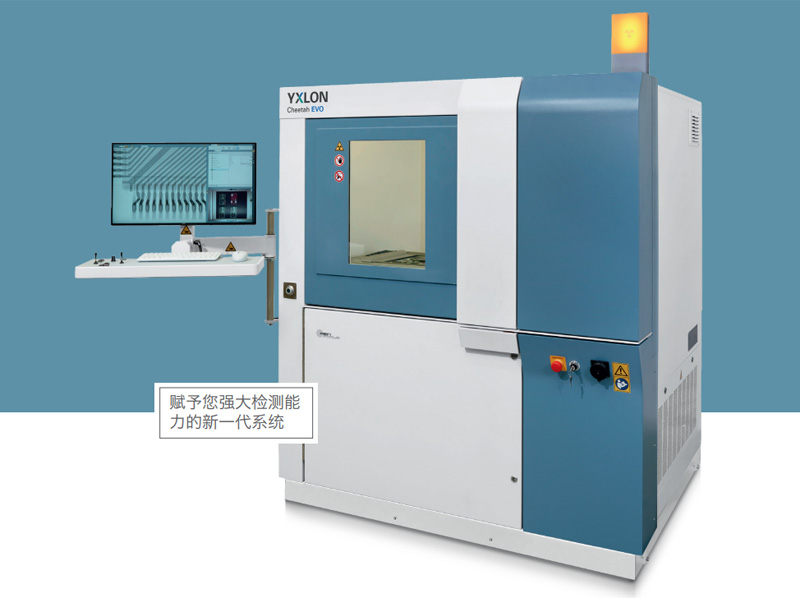

■ maximum process safety: flux quantity monitoring, gradient-controlled preheat process, automatic wave height control and many more

■ simple and comfortable teach process

■ processing of PCBs directly or in carriers up to 350 x 350 mm [13.78″ x 13.78″]

■ two individually configurable basic versions that are flexibly expandable

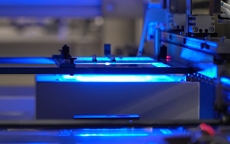

reliable flux deposition

reliable flux deposition energy-efficient preheat area

energy-efficient preheat area shortest cycle times with multiwaves

shortest cycle times with multiwaves